In the manufacture of fruit and vegetable purees, the bones and seeds are removed from the fruit or vegetables to package them crushed, mainly in 0.5 mm.

The puree is treated through a thermal process and aseptically packaged in drums with double high-barrier bags. The bags are placed in conical metal or cardboard drums that can be recycled.

It is used to make juices, dairy desserts and also pastries. At Baor Products we only manufacture and distribute non-GMO Purees, and they are also suitable for vegan and vegetarian diets. Our commitment to nature means that we manufacture eco-friendly and sustainable products. Fruit and vegetable purees are 100% natural and without any chemical treatment in their processes.

PEACH / PEACH 30-32

Peach puree is prepared from selected and washed fruit, crushed and passed through a metal mesh. The product is pasteurized with a high-short process and is packaged in aseptic and cooled drums.

Este proceso garantiza la conservación de todas las características organolépticas del puré de melocotón

Brix 10-12

Size 5 mm

Black Spot: <5/10 gr

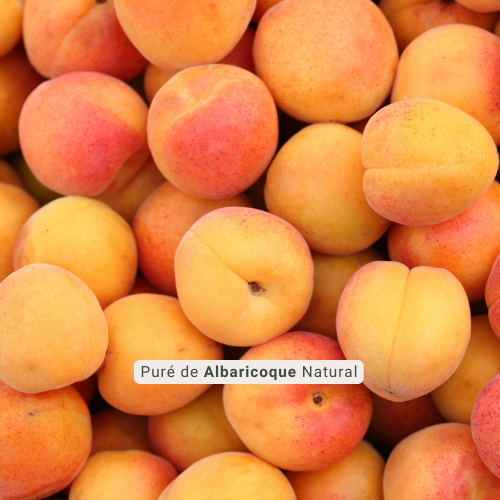

APRICOT / APRICOT CONCENRATE 30/32

Apricot puree is produced from selected and washed fruits, which are crushed and passed through a metal mesh. The product is pasteurized using a short high temperature process, and then packed in aseptic drums and cooled.

This process ensures the preservation of all the organoleptic characteristics of the apricot puree.

Characteristics:

Brix: 10-12

Size: 5mm

Black Spot: <6/10 gr

PLUM

Plum puree is produced from selected and washed fruits, which are crushed and passed through a metal mesh. The product is pasteurized using a short high temperature process and then packed in aseptic drums and cooled.

This process guarantees the conservation of all the organoleptic characteristics of the plum puree.

Depending on the variety of plum, we can operate in a brix range that goes from 10 to 17 for the Tolosa or Claudia Reina variety.

Characteristics:

Brix: 10-17

Size: 5mm

STRAWBERRY

Strawberry puree is produced from washed and selected strawberries of different varieties. The most used strawberry puree is the 0.5 mm sieve (without seeds).

The puree is packaged in metal drums with an aseptic bag. This process, together with refrigeration, guarantees the highest quality of the product.

We have two qualities:

Strawberry puree 0.5 mm without seeds

Strawberry puree 1.5 mm with seeds

APPLE

Apple puree is produced from selected and washed fruits, which are crushed and passed through a metal mesh. The product is pasteurized using a short high temperature process and then packed in aseptic drums and cooled.

This process guarantees the conservation of all the organoleptic characteristics of the applesauce.

Characteristics:

Brix: 10-12

Size: 5mm

Black Spot: <6/10 gr

KIWI

Kiwi puree is made from selected and washed fruits. These fruits are then crushed and passed through a 0.5 mm metal mesh. The product undergoes a short high temperature pasteurization process and is packaged in aseptic drums. Subsequently, it is stored refrigerated or frozen to maintain its characteristic deep green color.

This process guarantees the preservation of all the organoleptic characteristics of the kiwi puree.

Characteristics:

BRIX: Minimum 11

pH: 3.2-3.8

Acidity: Minimum 0.7

QUINCE

Quince puree is prepared from selected and washed fruit. The fruit is then crushed and passed through a 0.5 or 0.8 mm metal mesh. The product is pasteurized using a short high temperature process and packaged in aseptic drums, followed by cooling.

Quince puree is characterized by its high content of natural pectins from the fruit, which makes it a widely used ingredient for quince compotes or sweets.

Characteristics:

Brix: 10-12

Size: 5mm

Black Spot: <5/10 gr

RASPBERRY

Raspberry puree is made from selected and washed fruits, which are crushed and passed through a 0.5 mm metal mesh. The product is pasteurized using a short high temperature process and packaged in aseptic drums, followed by cooling.

Raspberry puree is widely used in the manufacture of red fruit juices and jams. IQF raspberry is also added to obtain the characteristic seeds.

Characteristics:

Brix: Minimum 7-10

Size: 5mm

Bostwick: Less than 20 cm / 30 sec

PEAR

Pear puree is made from selected and washed fruits, which are crushed and passed through a metal mesh. The product is pasteurized using a short high temperature process and packaged in aseptic drums, followed by cooling.

Characteristics:

Brix: 10-12

Size: 5mm

Black Spot: < 5/10 gr

LEMON

The lemon comminuted is made from washed and selected lemon peels. These skins are passed through a mesh to produce a puree, which is then subjected to an enzymatic process.

This process enriches the puree with citrus flavonoids such as hesperidin.

Characteristics:

Brix: Minimum 6.0

Acidity (% w/w) ACA: Minimum 0.6

pH: Maximum 3.5

ORANGE

The orange comminuted is made from washed and selected orange peels. These skins are passed through a mesh to produce a puree, which is then treated through an enzymatic process.

This process enriches the puree with citrus flavonoids.

Characteristics:

Brix: Minimum 7.0

Acidity (% w/w) ACA: Minimum 0.7

pH: 3.5

PUMKIN

Pumpkin puree is produced from selected and washed vegetables, which are crushed and passed through a 0.5 mm metal mesh. The product is pasteurized using a short high temperature process and packaged in aseptic drums, followed by cooling.

Pumpkin puree is widely used in the manufacture of vegetable creams. It has a characteristic intense orange color.

Characteristics:

Brix: Minimum 7-10

Size: 5mm

Bostwick: Less than 7 cm / 30 sec

GINGER

Ginger puree is made from the root of Zingiber officinale. This puree has numerous antiseptic and health-beneficial properties.

At Baor Products, we manufacture and distribute ginger puree in 20 kg containers, to facilitate its use in various productions.

Characteristics:

Brix: Maximum 5.0

pH: 6.0 – 7.0

Acidity: 0.01 – 0.09

CARROT

Carrot puree is produced from selected and washed vegetables, which are crushed and passed through a 0.5 mm metal mesh. The product is pasteurized using a short high temperature process and packaged in aseptic drums, followed by cooling.

Carrot puree is widely used in the manufacture of vegetable creams and juices. It has a characteristic intense orange color.

Characteristics:

Brix: Minimum 7

Size: 5mm

Bostwick: 3.0 – 7.0 cm / 30 sec

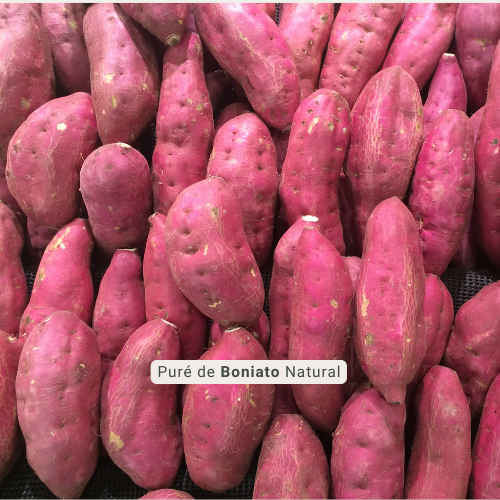

SWEET POTATO

Sweet potato puree is prepared from selected and washed vegetables, which are crushed and passed through a metal mesh. The mesh sieve is usually approximately 0.5 mm, which provides us with a homogeneous puree with a good texture.

The naturally sweet flavor of sweet potato makes it perfect for vegetable soups.

It is rich in vitamin A, vitamin E, carbohydrates and antioxidants combined with minerals. Plus, it’s low in fat. For this reason, it is suitable to include in diets.

BROCCOLI

Broccoli puree is prepared from selected and washed vegetables, which are crushed and passed through a metal mesh. The mesh sieve is usually approximately 0.5 mm, which provides us with a homogeneous puree with a good texture. When treating this vegetable, it is extremely important to control processing times to preserve the natural green color of broccoli.

We package in 200 kg aseptic drums, which we then keep refrigerated.

ZUCHINNI / COURGUET

Zucchini puree is mainly used in the preparation of vegetable creams, vegetable juices or smoothies.

The zucchini is washed, processed and packaged in aseptic drums as soon as it arrives from the field. The production process is carried out continuously in the same work day, in order to guarantee the properties of the final product.

CUCUMBER

Cucumber puree is prepared from selected and washed vegetables, which are crushed and passed through a metal mesh. The mesh sieve is usually approximately 0.5 mm, which provides us with a homogeneous puree with a good texture.

The product is packaged in 200 kg drums and stored refrigerated until the day of loading. This puree is mainly used as an ingredient in vegetable soups and smoothies. When making gazpachos, the cucumber puree is mixed with the rest of the ingredients to obtain the cold soup in a single production.

TOMATO

Tomato puree, also known in some places as NFC tomato, is mainly used to make juices and drinks.

Tomatoes are mainly harvested in August and September, and then processed aseptically.

Within the different types of tomato puree, depending on the sieve used during production, we can find several qualities that differ mainly by the thickness of the puree.

All of these grades have similar applications, and it is the factory’s knowledge and experience that determines which grade to use in each case.

PEPPER

Pepper puree has various applications. It can be used as an ingredient in vegetable creams, smoothies or as a filling for olives.

We offer both green pepper puree and red pepper puree. Both variants are made using the aseptic process and are available practically all year round.

to.

Within the different types of tomato puree, depending on the sieve used during production, we can find several qualities that differ mainly by the thickness of the puree.

All of these grades have similar applications, and it is the factory’s knowledge and experience that determines which grade to use in each case.

EGGPLANT

The eggplant puree is prepared from selected and washed vegetables, which are crushed and passed through a metal mesh. The mesh sieve usually has a size of approximately 0.5 mm, which provides us with a homogeneous puree with a good texture.

Eggplant has detoxifying properties and also acts as a diuretic due to its high potassium and folic acid content.

Furthermore, thanks to its diuretic properties, it contributes to the control of blood pressure. Eggplant is rich in nasunin, a compound that gives it all its properties.

The characteristic bitter taste of eggplant is due to the oxidation of its components and is related to the loss of properties.

Fruit and vegetable puree is a food product obtained from selected fruits and vegetables that have undergone processes of washing, crushing, and filtering through a metal mesh or another type of sieve. The purpose of this process is to achieve a consistent texture and a smooth consistency.

The result is a dense and uniform mixture that concentrates the natural flavors and nutritional properties of the fruits and vegetables used. The puree retains a significant portion of the nutrients, vitamins, minerals, and antioxidants present in these fresh ingredients. Furthermore, being processed in this manner, puree often has extended shelf life without the need for additives or preservatives, making it a convenient and versatile option in the food industry.

Fruit and vegetable puree can be used in a wide range of culinary and gastronomic applications. It is used as an ingredient in the preparation of juices, smoothies, sauces, soups, creams, fillings, desserts, and other food products. Its versatility makes it ideal for incorporating nutrients and flavor into various recipes, and its smooth texture facilitates its blending into various preparations.

BAOR’s fruit and vegetable puree manufacturing process is carefully planned and executed to ensure maximum quality, food safety, and preservation of the nutritional and organoleptic properties of the ingredients.

Ingredient Selection and Reception: Fresh and high-quality ripe fruits and vegetables are carefully chosen following strict selection criteria. These ingredients are inspected and washed to eliminate any contamination or impurities.

Preparation and Crushing: The washed ingredients are peeled, pitted, or deseeded as needed. Then, they are crushed into smaller particles to facilitate further processing.

Sieving: The crushed particles are passed through metal screens or other sieves to obtain a puree with a homogeneous texture and free from impurities. The choice of sieve size depends on the desired end product and the characteristics of the specific fruit or vegetable.

Pasteurization: The puree undergoes a pasteurization process using high temperatures for a short time. This eliminates pathogenic microorganisms and enzymes that could deteriorate the product while preserving its properties.

Packaging: The pasteurized puree is packaged in airtight and aseptic containers to prevent the entry of air and microorganisms. These containers may vary in size and material according to market needs and product requirements.

Cooling: Filled containers undergo rapid cooling to halt the cooking process and prevent the growth of microorganisms.

Storage and Distribution: The containers are stored in suitable facilities, such as refrigerated storage rooms, to preserve the quality and safety of the puree. Subsequently, they are distributed following established supply chains.

Quality Control: Throughout the process, quality and safety tests are conducted to ensure the product meets established standards. This includes sensory analysis, chemical, and microbiological analysis.

The ideal manufacturing process for fruit and vegetable puree is based on optimizing each stage to achieve a high-quality end product that preserves the nutritional and organoleptic properties of the fresh ingredients. Moreover, maintaining strict measures of hygiene and food safety is crucial to ensure the safety of the final product.

The debate over whether it’s better to consume fruit in its whole form or as puree has been of interest in the realm of healthy eating. Both options offer unique benefits and cater to different needs and preferences. Below, we will thoroughly examine the comparison between fruit puree and whole fruit to help you make informed choices in your diet.

Fruit Puree: The process of making fruit puree involves crushing and sieving the fruit, which can lead to a concentration of nutrients in an easier-to-consume form. Puree retains a significant portion of the vitamins, minerals, and antioxidants present in the fruit, although some heat- and oxidation-sensitive compounds may be lost during processing.

Whole Fruit: Consuming whole fruit allows you to take advantage of the fiber in its natural form, which is essential for digestive health. Additionally, chewing whole fruit contributes to a feeling of fullness and can help regulate appetite. Some vitamins and antioxidants may also be more stable in whole fruit.

Culinary Applications:

Fruit Puree: Fruit puree is versatile and can be used in a wide variety of recipes such as smoothies, sauces, desserts, and baked goods. Its smooth texture makes it easy to incorporate into different preparations and can be especially appealing to children and individuals with chewing difficulties.

Whole Fruit: Whole fruit is a convenient and portable option as a healthy snack. It is also ideal for adding to salads, cereals, or simply enjoying as it is. Chewing whole fruit can stimulate saliva production and improve digestion.

Personal Choice:

The choice between fruit puree and whole fruit depends on your nutritional goals, preferences, and individual needs. If you’re looking for a convenient way to obtain concentrated nutrients, fruit puree can be an excellent choice. On the other hand, if you value fiber and the experience of chewing fruit, whole fruit is the most suitable option.

Ultimately, combining both options in your diet can provide you with a complete range of nutritional benefits and satisfy your personal tastes. Adapting your consumption of fruit puree and whole fruit based on the occasion and your goals can be a smart strategy to make the most of the benefits of these natural and healthy foods.

Fruit puree is much more than a delicious and versatile option in the kitchen. In addition to its appealing taste and texture, this product offers a series of health benefits that make it a smart choice to integrate into your diet. Below, we will explore in detail the benefits that fruit puree can bring to your well-being:

Nutrient Concentration:

The fruit puree manufacturing process involves crushing and sieving the ingredients, creating a uniform and smooth consistency. This process also allows for the concentration of nutrients present in the fruit, including vitamins, minerals, and antioxidants. When you consume fruit puree, you are getting a concentrated dose of the nutritional benefits that these fruits have to offer.

Improved Digestion and Absorption:

The smooth and uniform texture of fruit puree facilitates digestion, which can be especially useful for people with digestive sensitivities or chewing difficulties. Furthermore, being in a already processed form, the nutrients in the puree are easier to break down and absorb by the body, potentially increasing their bioavailability.

Dietary Versatility:

Fruit puree is a highly versatile ingredient that can enrich a variety of recipes. From adding it to smoothies and yogurts to incorporating it into sauces and desserts, fruit puree can enhance the nutritional profile of your meals without additional effort. This versatility makes it a creative way to include more fruits in your daily diet.

Convenience and Storage:

One of the main advantages of fruit puree is its convenience. Being packaged in aseptic containers, fruit puree has a longer shelf life than fresh fruits. This means you can enjoy the nutritional benefits of your favorite fruits even when they are out of season. Additionally, its practical format allows you to take it with you as a healthy snack.

Option for Various Dietary Needs:

Fruit puree can be useful for individuals with specific dietary needs. For example, those requiring a modified texture diet due to chewing or swallowing issues can benefit from its smoothness. Furthermore, its nutrient concentration can be beneficial for people who need to increase their intake of vitamins and minerals.

WE DISTRIBUTE OUR PRODUCTS PROVIDING THE NECESSARY PACKAGING ACCORDING TO THE NEEDS OF OUR CUSTOMER

Leader in fruit and vegetable juices and concentrates, we stand out for excellence and innovation. Our products are 100% plant-based, sustainable and of high quality.

As international manufacturers and distributors, we guarantee safe and punctual deliveries. We work with you to boost the success of your business with personalized solutions fully adapted to your company.

Trust Baor to achieve your goals and enjoy a passionate and trustworthy collaboration!

Contact us today and discover how our concentrated fruit bases can propel your culinary vision to new heights.

All our products are stored at the appropriate temperature in state-of-the-art refrigerated facilities and chambers.

We manufacture and distribute internationally, preserving the cold chain, guaranteeing the quality of each of our products.

Our logistics operations through international operators guarantee the receipt of the product in perfect conditions.