19 Mar Discover the secret of deionized fruit for the manufacture of healthy treats

Murcia is one of the strategic places in the production of candy, and Molina de Segura, where Baor Products has its headquarters, concentrates three of the largest factories in Spain manufacturing candy of different types.

The ingredients of sweets are various, but they always need to have a sweetener, whether natural or artificial, depending on the demand of the product to be manufactured.

For years, many manufactures have gone through consumer awareness about the ingredients used as they seek increasingly healthier products. This has led to efforts to seek increasingly cleaner labeling and food innovation to move in this direction. satisfy the consumer

With the purpose of making increasingly healthier sweets, years ago fruit concentrates and fruit purees began to be used in the incorporation of candy pastes. Many of these products had the disadvantage of containing pulps that can affect the quality and stability of the final product. It was then that research began into the use of deionized fruit in the manufacture of different sweets.

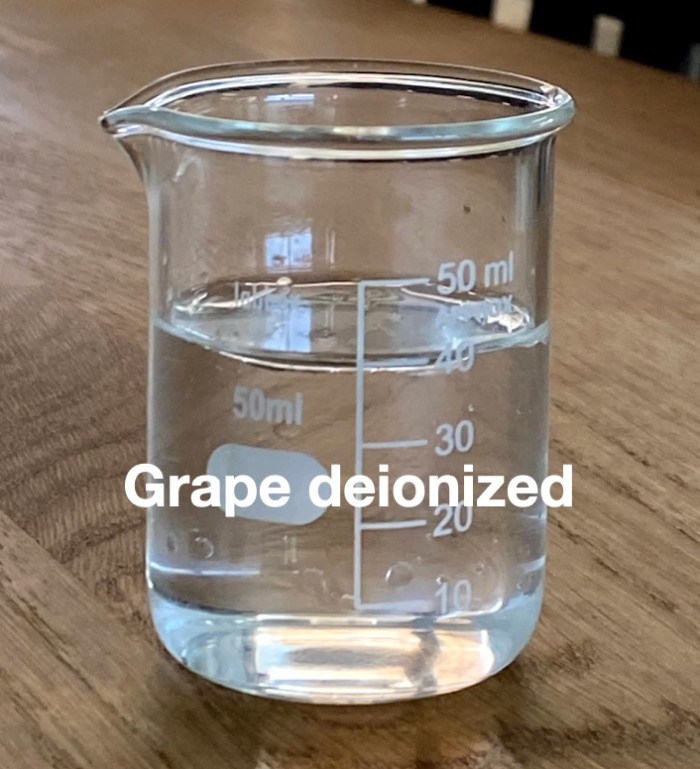

These deionized have the advantage of; In addition to having high brix necessary for production, they do not contain flavor or odor, only providing sugars from the fruit.

Thanks to the different developments, we can have mixtures of fruit sugars necessary to ensure, for example, that the candy does not have natural crystallizations, or that even provide vegetable fibers to the candy.

In the case of using concentrated plant fibers, the manufacturer even has the possibility of labeling the fiber on the final product.

How to make sweets with deionized fruit concentrate

Candy is made through a process that can vary depending on the specific type of candy being produced, but in general, the process consists of a series of standard processes.

The formulations can be different, but basically they usually include necessary ingredients, such as deionized fruit concentrate, gelatin, flavorings, natural colors and other additives depending on the type of candy being made.

The ingredients are mixed in food tanks with agitation or controlled temperature mixing, which helps the ingredients blend. In some cases, a premix must be made, where ingredients that require different processes or temperatures are integrated, as occurs in some cases with gelatin.

In the case of temperature, its control is very important, since in this way we will avoid unwanted caramelization of the final product, which would provide an unwanted flavor and color. In other cases, such as in candy manufacturing, we will need a specific temperature to achieve the desired consistency.

Once the ingredients and deionized fruit have been mixed, the hot mixture is poured into molds or passed through machines that shape the sweets. This may include cutting, rolling, stamping, or any other technique depending on the type of treat.

Once these sweets cool and harden, they are ready for packaging.

The trend towards the use of healthier ingredients such as deionized fruit in confectionery manufacturing reflects a broader shift towards greater awareness and concern for health and wellbeing among consumers, as well as a response from the food industry to meet those customer demands.

Sorry, the comment form is closed at this time.